Instructors Arthur S. Takeuchi & Mahjoub Elnimeiri

The design process for this pedestrian passageway was made with the surrounding context in mind. First and foremost it is a pedestrian bridge. Being on the junction between Chicago Avenue and Lake Shore Drive, the Museum of Contemporary Art as well as Navy Pier further down the Lake front played a big role in its conception.

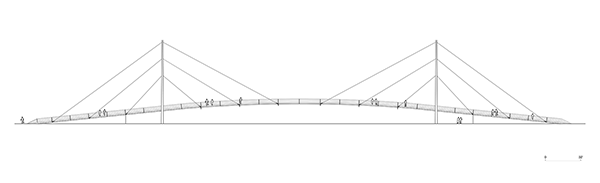

Not only did they determine the general orientation the bridge took - from west to south - but also its shape. Users coming mostly from the west, it was important to have visual cues to the promenade ahead. The slight rotation of the bridge upwards solves several problems encountered on this site. It gives visual clarity to the approaching users by giving them a full view of the bridge’s ramps - both incoming and outgoing and facilitates user perception. This shift also allows for the bridge to be symmetrical, an important feature architecturally and structurally.

Finally, the placement of the deck and ramps is tricky on this site, as the ramps of both ends total more than 150 feet each; the current placement makes this possible while avoiding existing trees on the way and respecting the necessary clearings for traffic and passers-by under the deck, as well as the placement of the pillars, that stay clear of any circulation patterns and don’t interrupt existing pedestrian flows.

The bridge was made as to be symmetrical, this is important visually but also architecturally. The construction is easier and the structure is more stable.

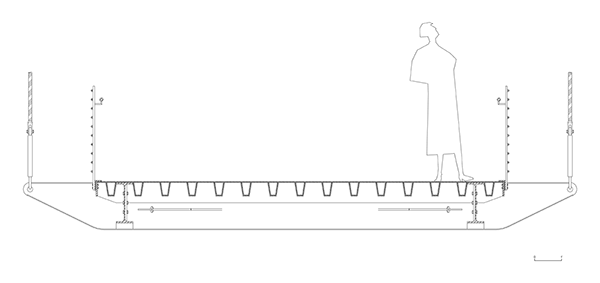

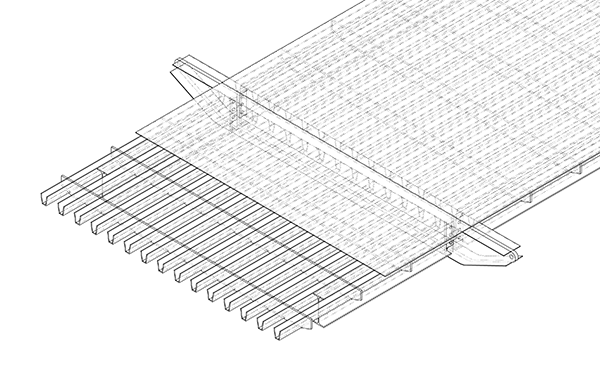

Because of the curve of the bridge, the deck is subjected to heavy torsion. The cables can take the load, but the structure isn’t stiff enough by itself. The bracing under the deck helps with the transmission of forces throughout the bridge to the pillars. The ramps are anchored to the ground and its cables act as back-stays for the spanning portion of the bridge.

The cables are few, so as to avoid dramatizing the structure more than necessary. By being fewer cables - and thicker - the bridge itself is also stiffer. This in turn helps with the torsion the deck suffers due to its curvature.

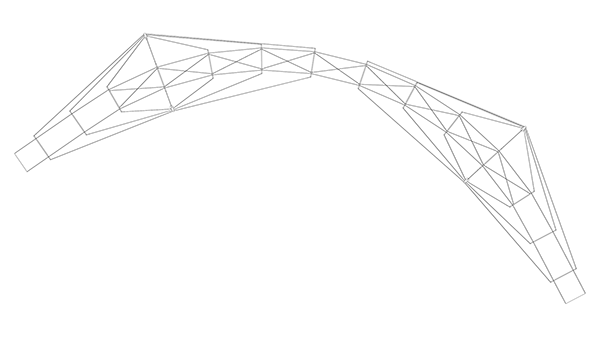

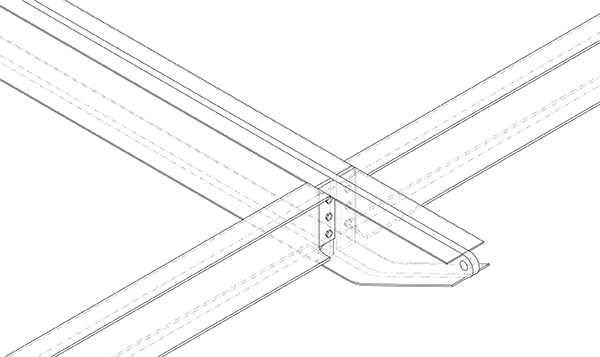

The curved part of the bridge - or to be more accurate, segmented - is made of self similar modules that can be prefabricated beforehand and transported on site separately and finally assembled together. The angle between the modules is always the same and the assembly to the primary beams is straightforward. The deck can be assembled with cranes from the adjacent sidewalks without disrupting traffic on Lake Shore Drive.